Garolite Care Hub

Troubleshooting: If filament no longer sticks to the plate, consider the following:

- Clean with IPA (preferably 99%) and a microfiber cloth.

- Alternatively, clean with other high-alcohol products like Ethanol (95%) or blue spiritus (70%).

- Clean with Warm water and dish soap, this seems to work wonders in some cases.

- Use a brim.

- Slightly increase the temperature (e.g., 62 degrees instead 55).

- Optionally, sand the plate with a fine grit (200 or finer) for a few moments. Ensure proper ventilation and safety measurements as Garolite contains glass fiber.

My plate is not reconised ? what can i do ?

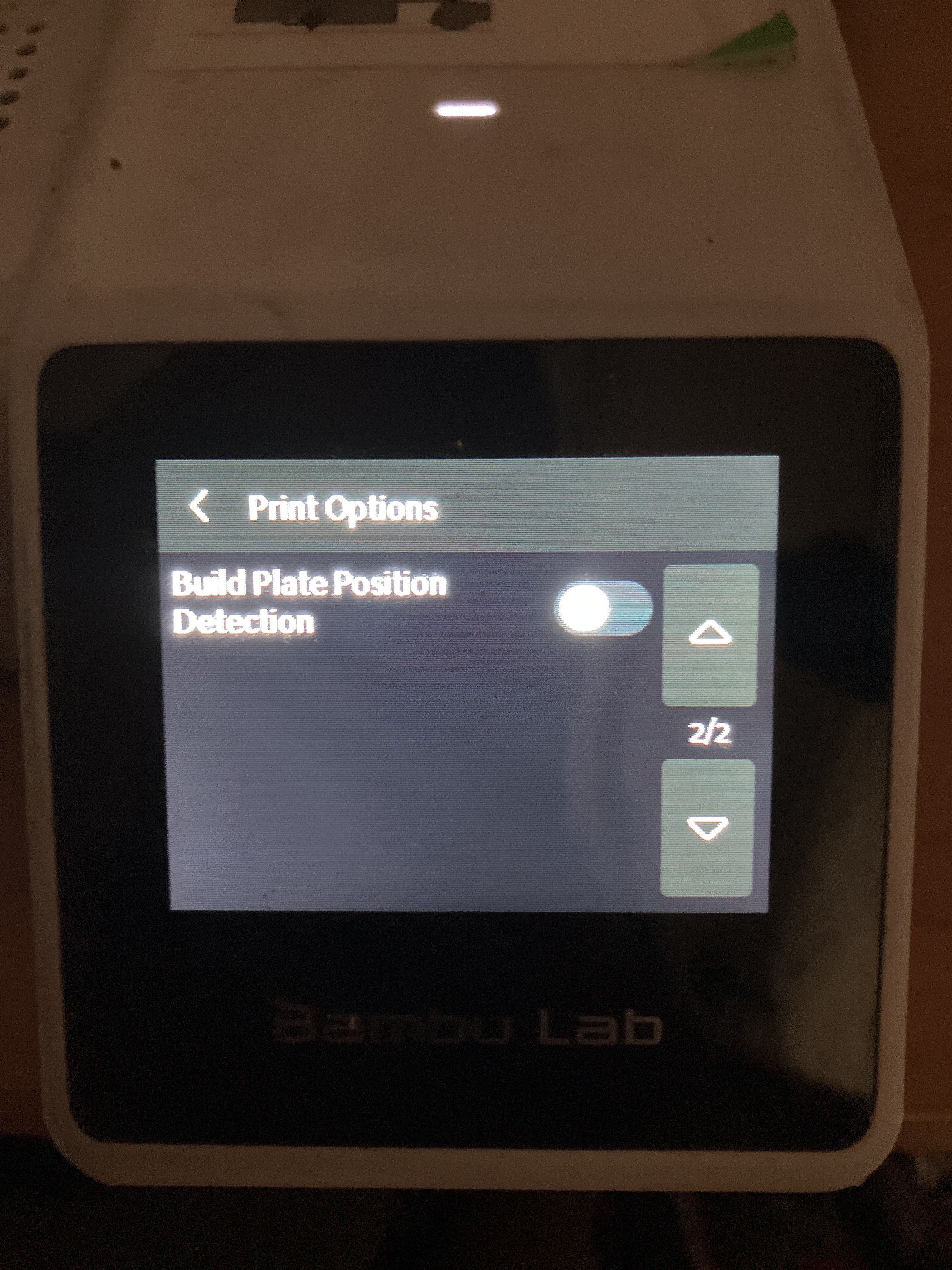

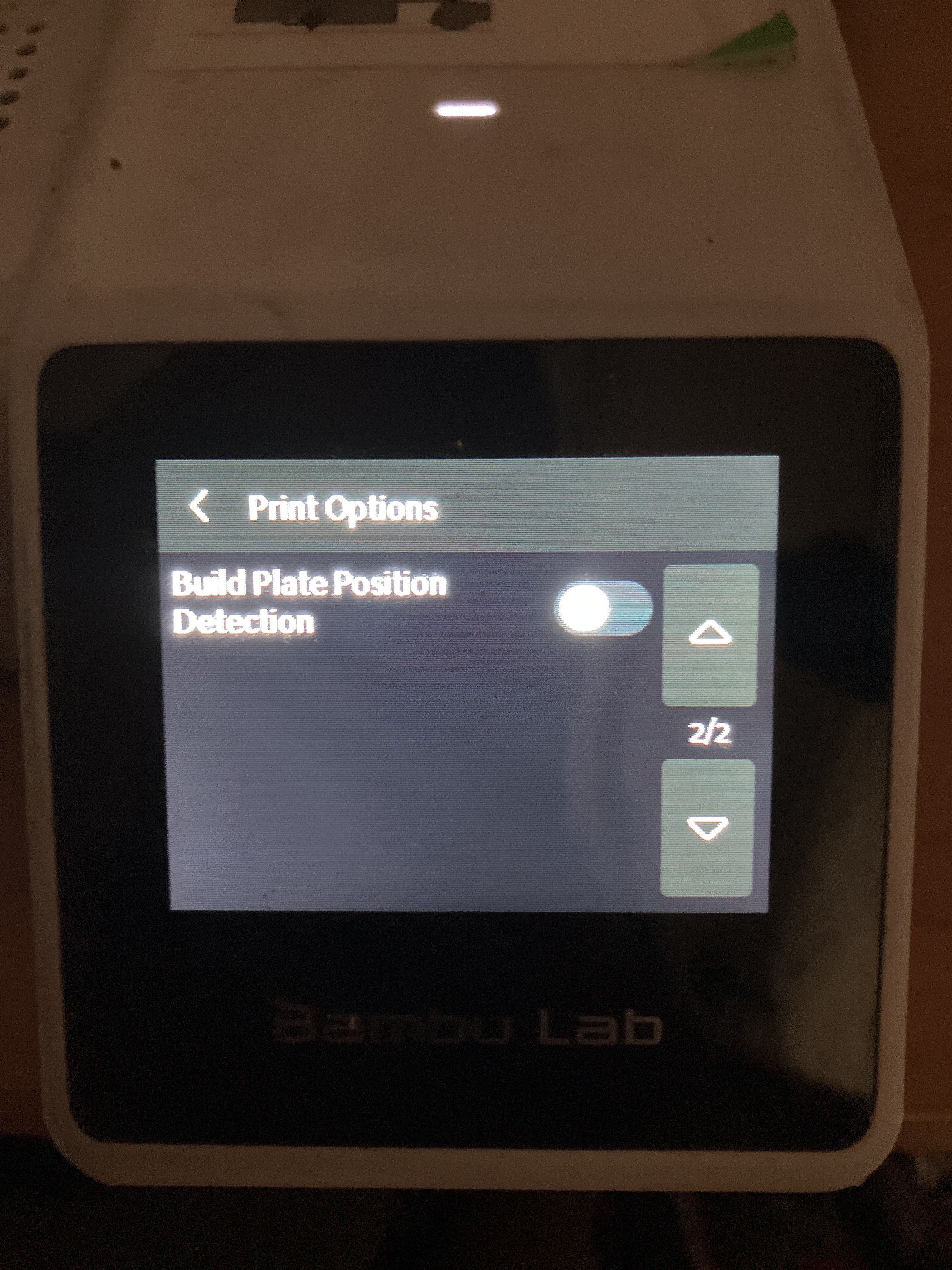

Please disable build plate detection on the A1 mini and other printers

The build plate does not always get reconised as official build plate, so it is better to disable it to prevent problems

Please disable build plate detection on the A1 mini and other printers

The build plate does not always get reconised as official build plate, so it is better to disable it to prevent problems

How to sand correctly:

first make sure you got a grid 200 or finer, how finer how better as you want to make micro cracks

so how to do the sanding a correct way

Do it with hand, no machine as that can make the thickness unequally and we want to prevent that

- Grab some sand paper of your choice ( grit 200 or higher )

- Go outside or in a well ventilated arena

- Wear a mask and goggles for safety, it is still fiberglass so the dust can hurt you

- sand the plate lightly in circles, you will see where you have been as there will be a fine layer of dust

- keep sanding it lightly until you see everywhere a light coat of dust, should take about 2 min

- take some ipa and spray it over the dust, this is to prevent that the dust goes to everywhere

- take paper tower and wipe it clean of the dust, repeat one more time to make sure all dust is gone

- after you take a look at the plate you will see fine scratches on it, this is good.

- try to print again as usual

- prints should stick firmy to it now

Filament Compatibility:

All filaments should adhere well to G10. Pla can have some trouble on G11 as G11 is more temperature sensitive and a bit more tricky for pla.TPU/TPE works wonders on G11, it sticks real hard to G10 but you wont damage the plate.

Never use a knife or any other sharp object, it can damage the plate and your knife wont like it

Glue Requirement:

No, Garolite does not need glue. In most cases, a brim is not necessary, though it can help in some instances.Plate Lifespan:

The plate should last for a couple of years.Ghost Image/Imprint:

Under normal circumstances, the plate does not leave a ghost image. However, some filaments may leave a ghost image, this image get removed over time if you print a couple times over it.Filament Compatibility Issues:

While most filaments work well on Garolite, some may not. Testing indicates that only 12 of the 14 polymaker colors worked, with two colors refusing to stick This was tested on G11 @ 0.5mm. with default settings ( no tweaking ).Recommended Temperature Settings:

Default temperature settings are suitable. For G11, it is suggested to go 5 degrees higher.Recommended Plate Settings (bambu):

Please select the smooth plate for optimal performance, there is no extra Z offset needed like a textured plate, so the high temp/smooth plate is the correct plate setting for bambu printers.Recommended Temperature Settings (Examples):

- For the X1C (Closed Workspace), use 63 degrees.

- For the A1 mini and A1 (open workspace), use between 63 and 65 degrees.

- For the Comgrow 500 (open workspace), also use between 63 and 65 degrees.

First Time Check: Ensuring Proper Logo Orientation on Build Plate

Locate the logo engraved on the top side of your build plate. This is the side where printing occurs. On the opposite side (the back), there should be a ferrofoil applied, typically appearing black.